During land or sea-based cargo shipment operations, it’s common to use shipping container twist locks on cargo ships to keep the containers from falling over.

Although you can stack containers and leave them be when they’re stationary, it’s a different story altogether when you stack them in ships or trains.

To prevent incidents of containers falling over from happening, shipping container twist locks come as the solution. Find out more about them here!

Also Read: Container Office Buildings and How They Benefit the Mining Sector

Contents

Maximum Number of Containers You Can Stack

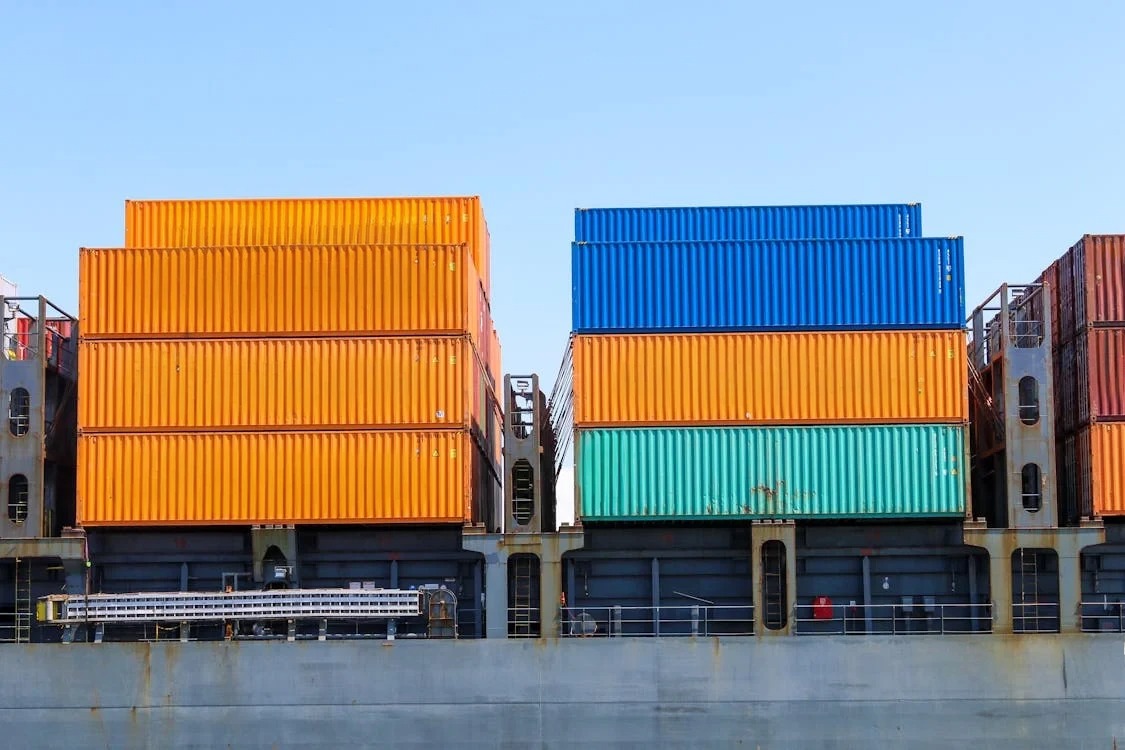

As we can see, stacking shipping containers is a common practice in shipping yards, ports, and on cargo ships, as well as in modular construction projects.

However, the maximum number of containers you can stack depends on several factors below:

- The containers’ types and weights

- The strength of the foundation

- The regulations or limits set by local authorities or shipping standards

If you pay close attention enough, you’ll often see containers stacked up to eight or nine high in cargo ships.

This is possible because the ship’s deck is engineered to support the massive weight and because the containers are designed to bear vertical loads through their corner posts.

On land, the number is usually lower due to wind loads and foundation limits; stacking three to six containers high is typical in most container yards or construction sites.

Even so, you can’t just stack containers and call it a day – there are several things you must consider when you want to do that.

Damaged or corroded containers should never be at the bottom of a stack, as they could compromise the entire structure.

If you stack container homes or offices as modular buildings, local building codes may further restrict stacking heights for safety reasons.

How to Securely Stack Shipping Containers

If you want to stack shipping containers anywhere (trains, ships, work sites), here’s how you do it right:

Inspect Containers

Check for structural integrity, especially at the corner posts and floors, and only choose containers in good condition.

Prepare the Site

Use a level, stable foundation-such as a concrete pad or compacted gravel base-to prevent shifting or settling (if you want to stack containers in work sites).

Align Precisely

Use cranes or container handlers to align containers so that each corner post sits directly on the one below, and have even weight distribution.

Choose Your Method

Most often, containers are stacked vertically, meaning each container sits directly atop another. Offset stacking (for creative builds) may require additional engineering and support.

Secure with Twist Locks

At every corner, use twist locks or other locking devices to connect containers and prevent shifting, sliding, or tipping.

Monitor Stability

Regularly inspect stacks for shifting, settling, or damage, especially after storms or heavy use.

Twist Locks for Stacking Containers

Whenever a cargo ship departs for a cargo shipment, chances are containers within it have shipping container twist locks fixed among them.

These mechanical devices fit into the corner castings of containers and lock them together, ensuring the stack stays put in rough seas, strong winds, or busy yards.

Twist locks come in several types, so let’s see which one is which that can help secure your containers during transit!

Horizontal Locks

Horizontal Twist Locks

To use this lock type, insert the cone-shaped end into the side corner casting of one container, twist to lock, then connect the second container and lock it in place.

They’re essential for stabilizing containers in modular buildings or on ships where lateral movement is a concern.

While you can’t use them for vertical stacking, they’re perfect for creating unified side-by-side structures.

Steel Bridge Fitting (Bridge Clamp Locks)

Bridge fittings are heavy-duty steel devices that clamp two adjacent containers together, preventing tipping or separation during sea transport or on-site use.

They come in various sizes (commonly 280 mm for 20-foot containers and 380 mm for 40-foot containers) and can be flush-mounted or raised for easier access.

Some bridge fittings use a dovetail design to distribute loads evenly and have ISO 1161 and CSC standards to allow them for regular use.

Vertical Container Locks

Semi-automatic Twist Lock

When you use this lock type, you pull the spring to the neutral position and insert the lock into the upper container’s corner casting.

The weight of the top container triggers the lock, which automatically secures the two containers together.

Semi-automatic locks use high-strength materials, can handle shear forces up to 42 tons, and are prized for their speed and safety in busy yards or ports.

They’re also highly durable and resistant to corrosion, making them a favorite for maritime use.

Manual Twist Lock

Manual twist locks – as befitting their names – are extremely straightforward and reliable.

Insert the cone-shaped end into the corner casting, then manually move the lever handle from left to right (neutral position) and then back to lock.

These locks are common for vertical stacking, offering a secure and cost-effective solution.

Lock Chassis Weld Type

This type of twist lock is welded directly onto the chassis of a container trailer.

Once the container is loaded onto the chassis, the lock is twisted to secure the container for road transport. This ensures containers remain firmly attached to the trailer, preventing movement during transit.

Welded chassis locks are essential for intermodal transport, where containers move between ships, trains, and trucks.

Dovetail-style Lock

Dovetail twist locks are designed for flat surfaces and can be welded, bolted, or cemented onto a base.

If you want to use this lock type, place the lock in position, load the container on top, and twist the lever to lock it.

Dovetail locks are especially useful for securing containers on concrete pads, steel decks, or other permanent surfaces.

Their design distributes loads evenly, making them ideal for semi-permanent or permanent installations in container-based buildings or storage yards.

Also Read: Shipping Container Workshop Design: How to Request Changes

Conclusion

So long as we use shipping container twist locks to secure containers when stacking them, we won’t have to be afraid of them falling over in cargo ships or trains. To ensure the containers themselves are secure by default, contact Tradecorp today! With their secure and well-designed construction, Tradecorp’s containers are perfect for use in any industrial setting.