CATEGORIES

- STANDARD CONTAINERS

- HIGH CUBE CONTAINERS

- SIDE OPENING CONTAINERS

- MINI CONTAINERS

- REFRIGERATED CONTAINERS

- INSULATED CONTAINERS

- OFFSHORE DNV

- MODIFIED CONTAINERS

- OFFICE CONTAINERS

- HAZMAT CONTAINERS

- ISO TANK CONTAINERS

- CONTAINER CHASSIS

- HALF-HEIGHT CONTAINERS

- OPEN TOP CONTAINERS

- COAL BIN CONTAINERS

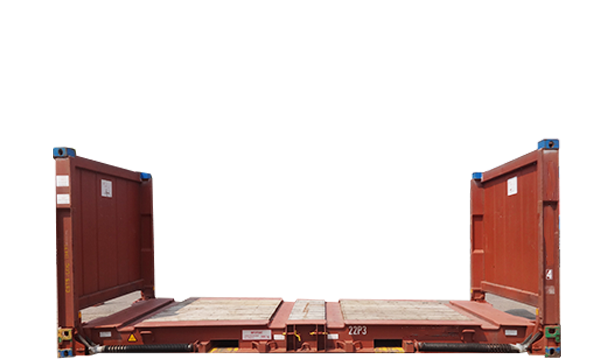

- FLAT RACK CONTAINERS

- BULKER CONTAINERS

- PALLET WIDE & CPC CONTAINERS

- REMOVALIST CONTAINERS

- TRANSIFLAT CONTAINERS

- CANOPIES

- GENSET CONTAINERS

A Specialized Solution for Irregular Cargo

Not every shipment fits neatly inside a standard box. When you’re moving wooden logs, steel pipes, generators, tires, construction modules, or other bulk items that won’t fit into standard containers, a flat rack container is the right tool. Tradecorp supplies and rents the flat rack shipping container you need for efficient transportation—purpose-built for oversized and awkward cargo types that demand strength, securement, and fast loading and unloading.

What Makes a Flat Rack Container Unique?

A flat rack container is essentially a reinforced steel deck with end walls. Unlike a conventional box, flat racks only have walls at the front and rear—no side walls, no roof—so cranes and forklifts can load from the top or the sides with minimal handling. Available in 20’ and 40’ lengths, you can choose fixed-end or collapsible flat racks depending on how you plan to stage and return equipment. For extra tall items or top-entry work, open top handling is inherent to the design.

- Use cases: out-of-gauge machinery, beams, reels, vehicles, tanks, prefab modules

- Flexibility: easy lash-down points and direct crane placement reduce dwell time

- Compatibility: engineered to interwork with ships, railcars, and trucks across lanes

Key Features and Construction

Built from weather-resistant Corten steel and engineered for heavy duty performance, Tradecorp’s flat racks handle heavy loads with confidence while protecting your assets in transit and yard operations.

- Corner castings for secure stacking and intermodal handling

- Forklift pockets for safe ground moves and yard positioning

- Lashing rings and lashing winches (model-dependent) to restrain cargo securely

- High working load limits to accommodate dense, high-mass freight

- Collapsible ends available to reduce backhaul cost when empty

Cost effectiveness is built in: faster handling, fewer special moves, and the ability to consolidate large items onto one platform cuts total move costs compared to piecing together multiple smaller shipments.

Expanded Range and Capabilities of Flat Rack Containers

Tradecorp offers a flat rack container for sale or rent to match your route, schedule, and cargo profile. From standard 20’ platforms to 40ft heavy duty frames with high deck strength, our fleet supports industrial moves, project cargo, and rack shipping of gauge OOG (out-of-gauge) freight that simply can’t ride inside a traditional box.

- 20’ flat racks: compact footprint, ideal for dense machinery and concentrated masses

- 40’ flat racks: additional deck length for beams, pipe, long fabrications, and vehicles

- Collapsible flat racks: fold the ends to reduce volume and reposition economically

- Fixed-end flat racks: maximum rigidity and end-wall protection during transit

Where projects require top placement by crane or side lift, the open top nature of flat racks keeps the workflow smooth and predictable.

Flat Rack Container Dimensions and Types

While dimensions vary by manufacturer and rating, most models adhere to ISO footprints for seamless intermodal moves. Below are general guidelines (speak with our team for current flat rack container specifications):

20ft Flat Rack (Typical)

- External length ~20’; standard width and height at end frames

- Best for compact, cargo worthy heavy machinery, pumps, skids, reels

- Collapsible options allow multiple empties to be stacked on top of one another for repositioning

- High deck strength relative to footprint for heavy loads

40ft Flat Rack (Typical)

- External length ~40’ with reinforced end frames

- Suited to long items—steel beams, pipe strings, lattice components, vehicles

- Often fitted with lashing rings/winches to secure OOG shapes

- Available in heavy duty variants for extreme mass and center-of-gravity control

Because flat racks only have walls at the ends, cargo overhang that’s within carrier policy can ride safely—making them indispensable for gauge OOG transport where height, width, or length exceeds standard box clearances.

Flat Rack Container Specifications (What to Ask For)

Every project is different. When you request a quote, share your flat rack container specifications so we can match the right unit:

- Required length: 20’ vs 40ft

- Weight profile: gross mass, center of gravity, lift points

- Footprint & overhang: true length/width/height, including accessories

- Tie-down plan: quantity, rating, and placement of lashing rings

- Handling method: crane only, side-loader, forklift, or mixed

- Backhaul plan: need collapsible ends to improve empty return cost effectiveness?

Tradecorp will confirm allowable loading patterns, deck ratings, and restraint methods so your shipping flat rack container is compliant and ready on arrival.

What are the Advantages of Flat Rack Shipping Containers with Tradecorp?

Choosing a flat rack shipping container for sale or rental from Tradecorp gives you predictable performance with the support of a project-cargo team.

- Cost effectiveness: Consolidate big pieces onto fewer platforms; minimize special rigging; cut handling time.

- Versatility: Fixed or collapsible end walls; 20’ and 40’ footprints; open top handling for cranes and side lifts.

- Durability: Corten steel construction and heavy duty frames for mission-critical cargo types.

- Operational speed: Loading and unloading is faster when you can approach from the top/side and lash down quickly.

- Intermodal ready: ISO footprints and corner castings simplify transfers between ship, rail, and truck for truly efficient transportation.

Whether you’re moving plant equipment to a remote jobsite or staging an export of oversized steel fabrications, flat racks keep the schedule—and budget—on track.

What are the Best Practices for Loading and Unloading Flat Racks?

A successful rack shipping plan starts with safe handling and securement. Keep these fundamentals in mind:

- Pre-plan placement

Map where each piece will sit to keep a low, centered CG. Avoid point-loading beyond deck limits. - Use rated gear

Select chains/straps matched to mass and geometry. Attach to the provided lashing rings at proper angles. - Protect contact points

Dunnage, cribbing, and edge protection reduce slip and prevent coating damage to cargo and deck. - Verify clearances

For gauge OOG moves, confirm terminal and carrier policies on over-width/height and route restrictions. - Mind the lift

For crane lifts, taglines and spreader bars help prevent swing and twist. For forklifts, use the forklift pockets as intended. - Document the tie-down

Photos and torque checks support carrier acceptance and cargo claims prevention.

Following these steps reduces rework and ensures your flat rack container is accepted by terminals and carriers the first time.

Applications: When a Flat Rack Is the Right Call

- Construction & energy: turbines, gensets, transformers, lattice towers

- Steel & fabrication: long beams, plate bundles, welded modules

- Mining & heavy industry: crushers, mills, tracked vehicles, buckets, reels

- Automotive & equipment: specialty vehicles, excavators, large attachments

- Infrastructure: bridge segments, pipe spools, culverts, precast forms

If it’s too tall, too wide, too long—or simply too dense—to ride in a box, a flat rack container makes efficient transportation possible.

Get Your Flat Rack Shipping Container for Sale or Rent

Tradecorp keeps projects moving with the right platform, at the right time, and at the right price. Whether you need a single unit or a staged fleet, we’ll configure a flat rack container for sale or a flexible rental tailored to your route and schedule:

- 20’ or 40’ flat rack shipping container

- Fixed-end and collapsible models

- Heavy duty frames for extreme heavy loads

- Accessory options: additional lashing rings, winches, dunnage kits

- Guidance on flat rack container specifications and carrier acceptance

Tell us about your cargo and timeline, and our team will recommend the best shipping flat rack container to maximize cost effectiveness without compromising safety.

Ready to move out-of-gauge freight? Contact Tradecorp today for pricing and availability on a flat rack shipping container for sale or rent—and experience how the right platform turns complex logistics into a smooth, predictable move.