Looking for ISO Tank Containers for Sale?

Exploring Uses & Types

Ready for bulk orders.

ISO-certified supplier

When you need a dependable ISO tank container—for chemicals, food-grade ingredients, fuels, or industrial gases—Tradecorp delivers. We stock a wide range of iso tanks for sale and for rent, built to strict ISO standards and supported by expert guidance on selection, compliance, loading and unloading, and lifecycle care. From standard liquid tanks to cryogenic and gas tank models, we tailor a container ISO tank solution to your operation, lead time, and budget.

- Our tank containers are available in multiple types and sizes

- We provide tailor-made configurations for specialized cargo

- Bulk and project orders welcomed with coordinated logistics

Our tank containers are available in various types and sizes

We are experts in providing tailor-made solutions for tank containers to meet diverse requirements

Get A Quote For Iso Tank Container Products

Tell us about your cargo, route, and desired term (buy or rent), and we’ll recommend the right iso tank container for sale or rental—complete with accessories, certifications, and delivery options.

What is an ISO Tank Container?

An ISO tank is a pressure vessel housed in a standard 20ft or 40ft frame, designed for transporting liquid and liquids gases safely and efficiently across road, rail, and sea. Constructed primarily from stainless steel with protective cladding and insulation options, the tank and frame conform to ISO standards, ensuring intermodal compatibility and predictable handling. Applications span hazardous materials and non-hazardous cargo alike, including hazardous chemical products, edible oils, wine, solvents, fuels, cryogenic gases, and more—making the ISO tank a proven, scalable answer for bulk logistics and iso tank storage.

Tradecorp offers:

- T50 gas tanks

- T75 cryogenic tanks

- ISO chemical tanks

- ISO T11 liquid tanks

- ISO offshore DNV tanks

- ISO pneumatic tank containers

- T6 hazardous liquid tanks

ISO Certification: Quality Assurance for ISO Tank Containers

All Tradecorp tanks meet relevant ISO certification and modal testing requirements for Series 1 portable tanks. That means:

- Verified design pressures and shell thicknesses

- Approved relief devices and bottom outlet arrangements

- Compatibility with road/rail/sea intermodal operations

- Documentation to support hazardous cargo compliance

Choosing Tradecorp’s certified tanks helps ensure regulatory alignment and dependable performance for loading and unloading, carriage, and iso tank storage at destination.

The Advantages of ISO Tank Containers

Discover Our Wide Range of ISO Tank Containers to Suit Your Specific Needs

Versatility

A single fleet can carry food-grade liquids, hazardous chemical cargoes, and specialty products (with proper cleaning and lining choices). Options include steam heating, insulation, linings, and instrumentation for tight temperature and process control.

Efficiency

ISO tanks maximize payload per trip, minimize residue, and speed loading and unloading compared to drums or IBCs. They reduce packaging waste and streamline cleaning cycles—boosting asset utilization and lowering total logistics cost.

Safety

Engineered from stainless steel and built to ISO standards, tanks undergo rigorous pressure, leak, and structural testing. Relief valves, emergency vents, earthing points, and anti-slip access improve safety for crews and protect the environment.

ISO Standard

Standardized footprints and fittings mean easy stacking, securement, and intermodal handoffs. Your iso tank integrates seamlessly with global terminals and depots for transport and iso tank storage.

T Code System for ISO Tank Containers and Specifications

Many chemicals are governed by the IMDG Code’s portable tank instructions (T1–T22) that specify minimum test pressure, thickness, relief devices, and bottom outlet requirements. In general, T11 is the common workhorse for general liquid chemicals, while T23, T50, and T75 address specialized self-reactive cargo, pressurized gases, and cryogenic liquids gases respectively.

| T-Code | Minimum Test Pressure (bar) | Minimum Shell Thickness | Pressure-Relief Requirements | Bottom Opening Requirements |

|---|---|---|---|---|

| T1 | 1.5 | > or = 6mm | normal | 2 shut-off devices (Int + Ext) |

| T2 | 1.5 | > or = 6mm | normal | 3 shut-off devices (Int + Ext + cap/blank) |

| T3 | 2.65 | > or = 6mm | normal | 2 shut-off devices (Int + Ext) |

| T4 | 2.65 | > or = 6mm | normal | 3 shut-off devices (Int + Ext + cap/blank) |

| T5 | 2.65 | > or = 6mm | normal + rupture disc | Not Allowed |

| T6 | 4 | > or = 6mm | normal | 2 shut-off devices (Int + Ext) |

| T7 | 4 | > or = 6mm | normal | 3 shut-off devices (Int + Ext + cap/blank) |

| T8 | 4 | > or = 6mm | normal | Not Allowed |

| T9 | 4 | 6mm | normal | Not Allowed |

| T10 | 4 | 6mm | normal + rupture disc | Not Allowed |

| T11 | 6 | > or = 6mm | normal | 3 shut-off devices (Int + Ext + cap/blank) |

| T12 | 6 | > or = 6mm | normal + rupture disc | 3 shut-off devices (Int + Ext + cap/blank) |

| T13 | 6 | 6mm | normal | Not Allowed |

| T14 | 6 | 6mm | normal + rupture disc | Not Allowed |

| T15 | 10 | >or = 6mm | normal | 3 shut-off devices (Int + Ext + cap/blank) |

| T16 | 10 | > or = 6mm | normal + rupture disc | <3 shut-off devices (Int + Ext + cap/blank)/td> |

| T17 | 10 | 6mm | normal | 3 shut-off devices (Int + Ext + cap/blank) |

| T18 | 10 | 6mm | normal + rupture disc | Not Allowed |

| T19 | 10 | 6mm | normal + rupture disc | 3 shut-off devices (Int + Ext + cap/blank) |

| T20 | 10 | 8mm | normal + rupture disc | Not Allowed |

| T21 | 10 | 10mm | normal | Not Allowed |

| T22 | 10 | 10mm | normal + rupture disc | Not Allowed |

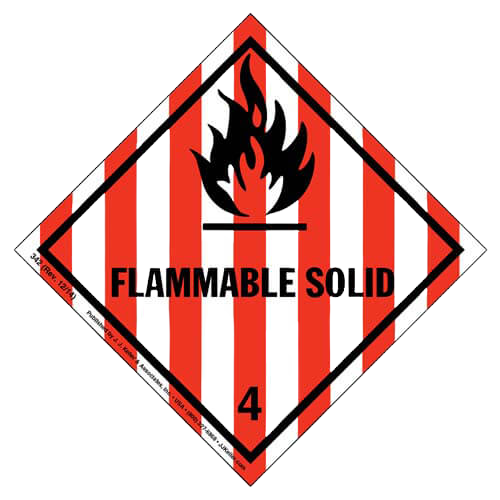

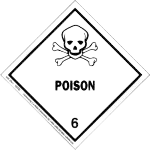

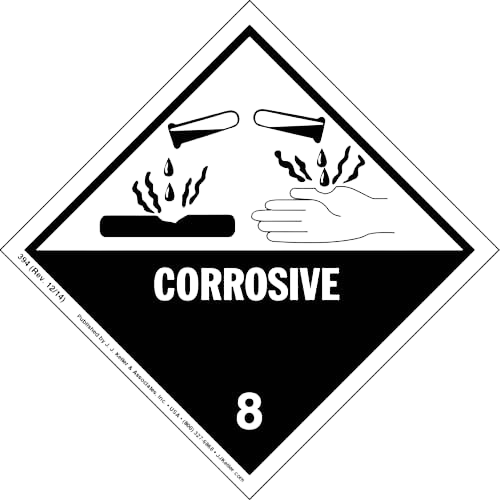

Tank types T1 to T22 are assigned to various dangerous goods of class 1, classes 3 – 9 solids and liquids. T23 is for certain self-reactive substances type F and certain organic peroxides of type F. T50 is for non-refrigerated liquefied gases and certain chemicals under pressure and T75 is for refrigerated liquefied gases.

| Container type | Ideal usage |

|---|---|

T1 ISO tank container: | Wine and light liquids |

T3 ISO tank container: | Asphalt |

T4 ISO tank container: | Non-hazardous edible & non-edible oils |

T11 ISO tank container: | Non-hazardous chemicals |

T14 ISO tank container: | Hazardous chemicals/acids (e.g., HCl, zinc chloride) |

T20 ISO tank container: | Corrosive liquids (HCl, ferric chloride, NaOCl, HF) |

T50 ISO tank container: | LPG, ammonia (pressurized gas tank) |

T75 ISO tank container: | Cryogenic gases (refrigerated liquefied) |

Purpose-built for asphalt and fuels, this tank features robust construction and heat tolerance to maintain workable viscosity. Capacity around 22,000 L; engineered for elevated service temperatures and compliant with relevant codes for secure transporting liquid hydrocarbons.

A 20ft stainless steel solution for oils and food grade products, classified by LR/BV and designed under ASME VIII Div. 1. Typical effective capacity: 19–26 m³; working pressure ~0.18 MPa. Corrosion-resistant and suitable for edible and non-edible liquids.

Built for hazardous materials, the T6 includes spill containment, grounding lugs, non-slip access, and compliant labeling for flammable, corrosive, toxic, or explosive liquids. Focused on personnel, cargo, and environmental safety during loading and unloading.

Specifications

| Max Gross: | 36,000 kg |

| Tare: | ~3,850 kg |

| Capacity: | ~24,000 L |

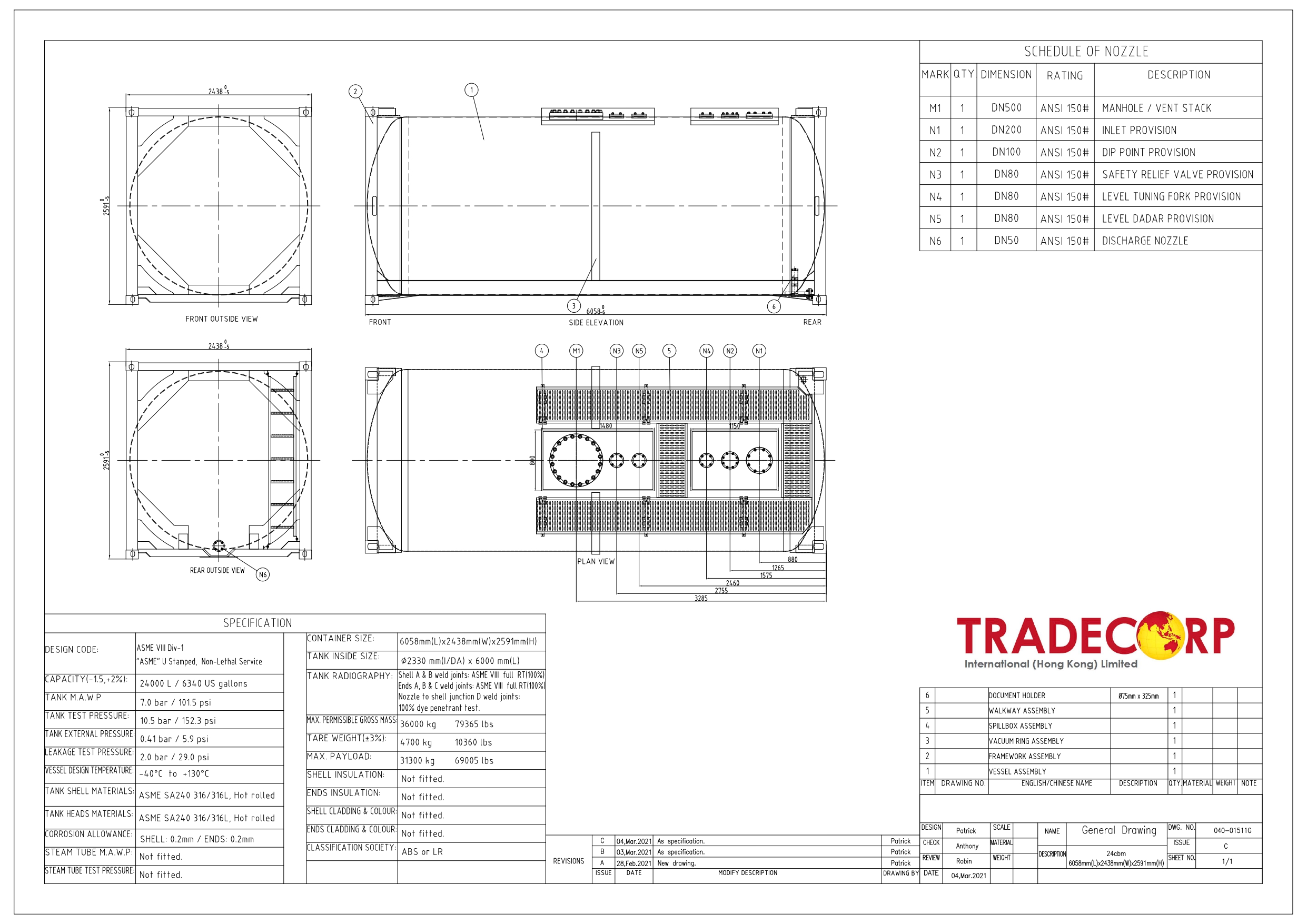

A stainless-steel pressure vessel (often 316L) for a wide spectrum of cargo—from alcohols and oils to chemicals and pharmaceuticals. Options: steam/electric heating, inert gas blanketing, temperature sensors, and insulation to control cargo quality throughout transit and iso tank storage.

Designed for HCl and similar corrosives with appropriate metallurgy/coatings, safe access, anti-skid walkways, and defined top/bottom transfer points. Robust external and internal protections guard against corrosion and accidental release of hazardous chemical cargo.

Specialized for TiCl₄ with corrosion-resistant build, secure access, and strict sealing requirements. Engineered to meet handling specifics of this highly reactive hazardous cargo during loading and unloading.

The industry’s generalist for non-hazardous chemicals and many food-grade products. Stainless steel construction, relief devices, emergency venting, and lining options prevent contamination and extend tank life. Available to buy or rent.

Specifications

| Max Gross | ~79,366 lbs |

| Tare | ~8,068 lbs |

| Net | ~71,297 lbs |

For more aggressive cargo, these classes add higher test pressures, specialized linings, steam runs, baffles, and upgraded PRVs to handle demanding service while maintaining safety and product integrity.

For hazard classes 3, 5.1, 6.1, 8, and 9, with thermal insulation and optional heating to condition product before discharge. Fort Vale valves and service platforms support safe operation and efficient loading and unloading.

Engineered specifically for water-reactive cargo such as TEAL (UN3394). Compact but highly robust, with defined pressure/temperature envelopes and compliant materials to meet stringent handling protocols.

A high-spec tank for particularly hazardous cargo, with extensive steam heating, level gauging, manlids/spill boxes, and optional baffles to reduce liquid surge and improve stability during transit.

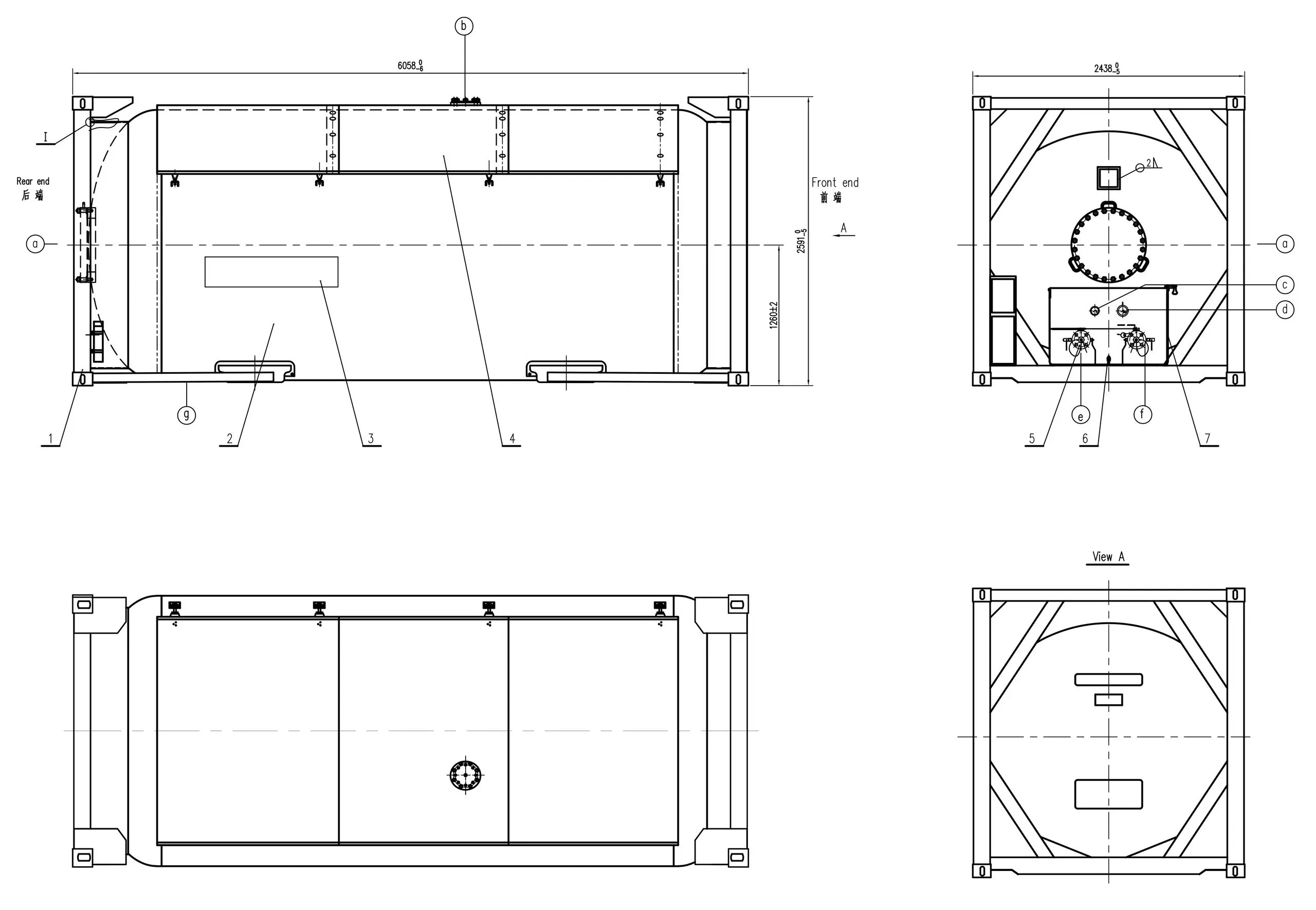

T3 Tank Container

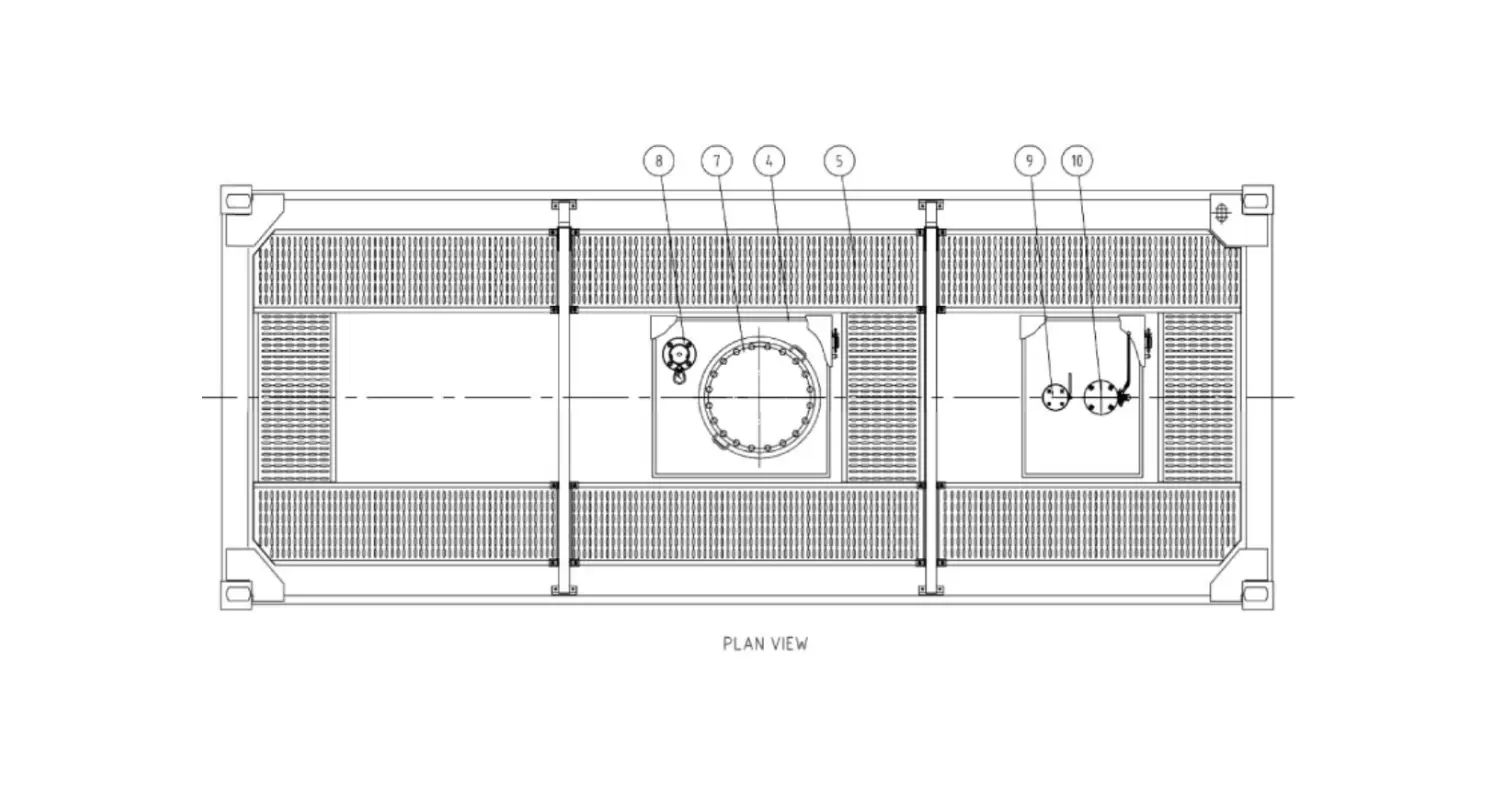

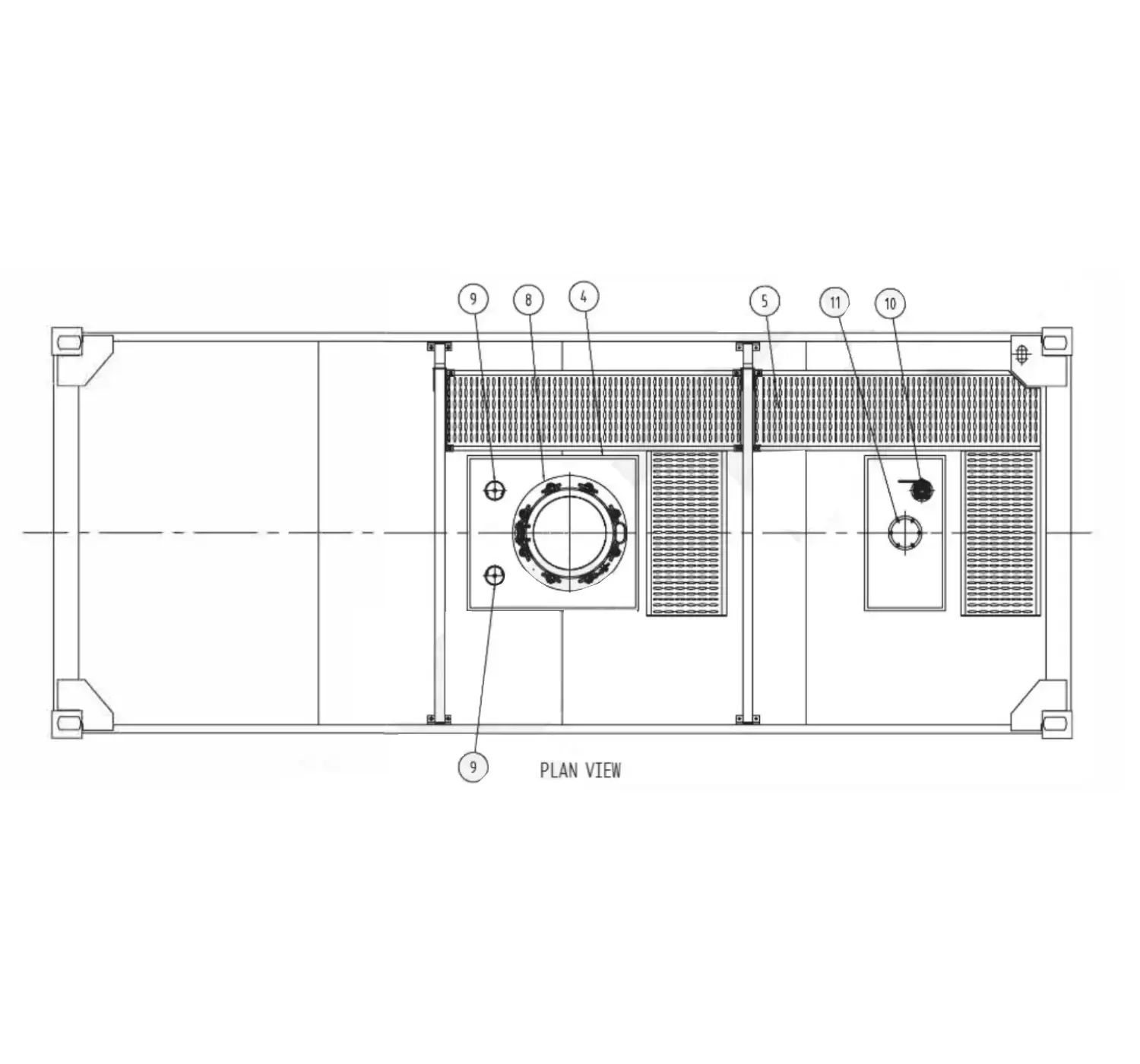

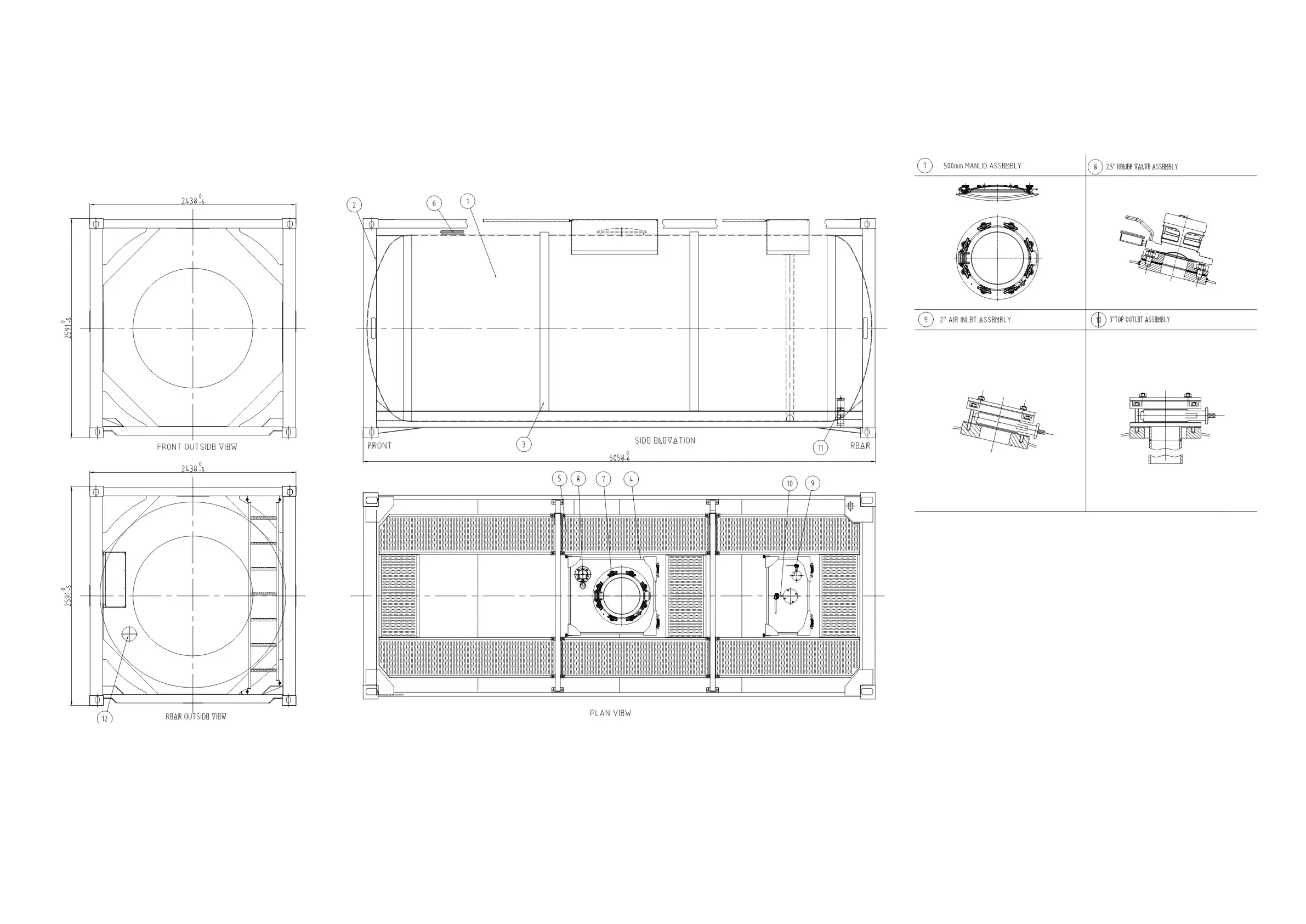

The T3 tank container is designed for the transportation and storage of asphalt, petrol, or fuels. It has a length of 6058mm, width of 2438mm, and height of 2591mm. The maximum gross weight is 26000 kg, with a tare weight of 4.85 tons and a payload capacity of 21000 kg. The nominal capacity of the tank is 22000L. It meets design standards such as IMDG-CODE, GB150-98, ASMI-1, and JB/T4781-2005. The tank is recognized by CCS and complies with various shipping requirements such as IMDG, CSC, TIR, UIC, RID, ADR/IMO/ISO. It is a 20FT tank with a column shape in a horizontal orientation. The design temperature ranges from -40ºC to +130ºC, with a design pressure of 1.75bar. The working pressure is 0.9bar, and the working temperature is 230ºC. The tank has undergone various tests, including a hydraulic pressure test at 2.6Bar, gastight test pressure at 1.2bar, vacuum test pressure at 0.21Bar, and 100% X-ray radiographic inspection. The tank is made of high-quality mild steel (GBQ345B) with a thickness of 5.0mm. The end enclosure has a thickness of 5.0mm, and the washplate has a thickness of 4mm with 2 compartments and 1 bin.

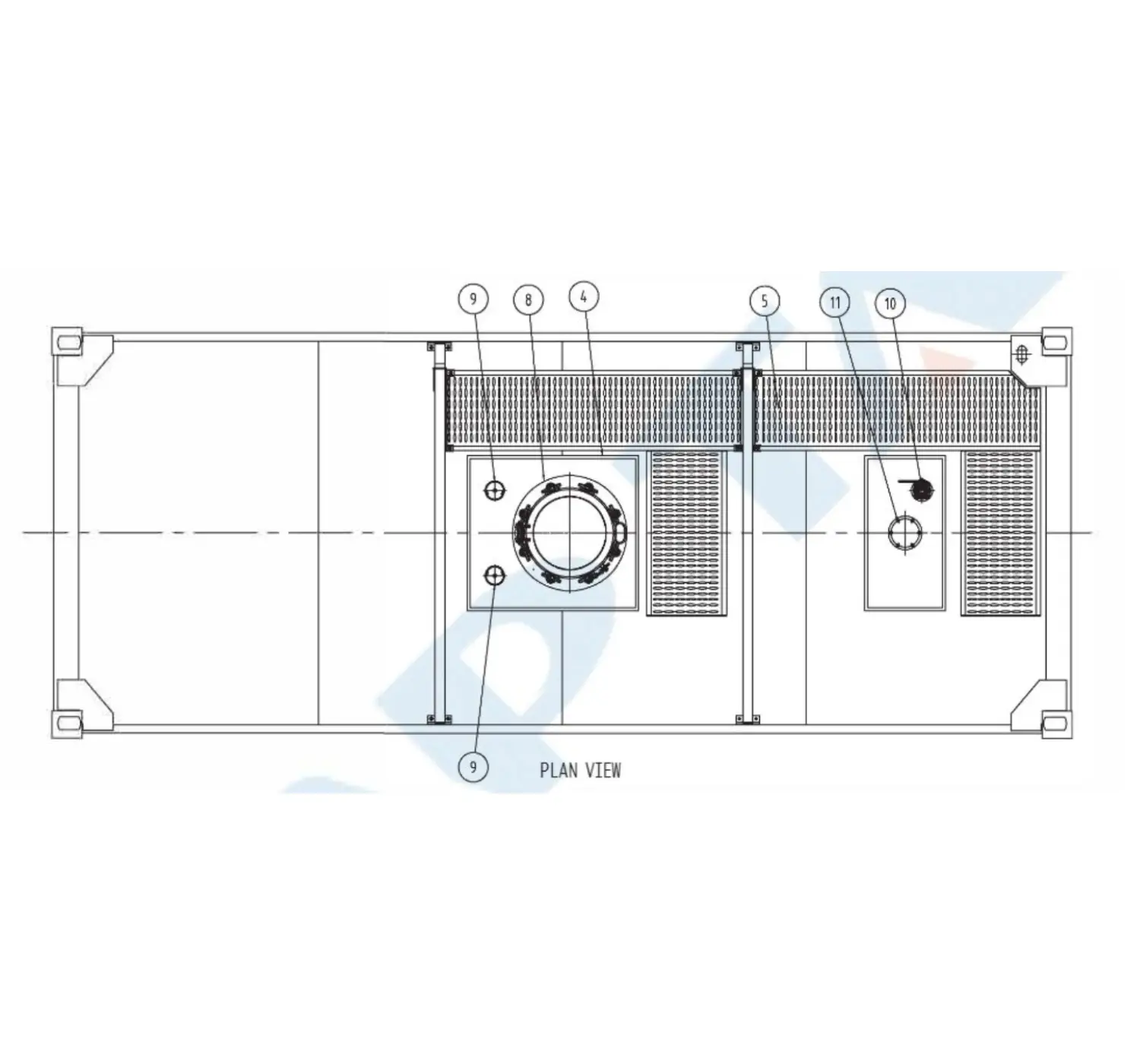

T4 Tank Container

The T4 ISO Tank Container is a high-quality storage and transportation solution designed for various applications. It has a specification of 20ft and meets the design standard of ASME VIII DIV. 1. The tank container is classified by LR/BV, ensuring its compliance with industry regulations and standards. With an effective capacity ranging from 19 to 26 m³, it offers ample storage space for a variety of substances. The working pressure of the tank container is 0.18 MPa, providing a safe and reliable environment for the contained materials. Constructed with durable and corrosion-resistant stainless steel 304, the tank container guarantees the integrity of the stored contents. It is suitable for handling petrochemicals, oils, and food-grade liquids, making it a versatile choice for different industries and applications. Whether it’s for industrial or food-related purposes, the T4 ISO Tank Container offers a secure and efficient solution for the storage and transportation of liquids.

T6 Tank Container

A T6 dangerous liquid tank is specifically designed to carry and store hazardous liquids safely. They are typically made of stainless steel, carbon steel, or aluminum, and are equipped with safety features like a spill containment system, earth/ground lug, non-slip stainless steel ladder, and walkway. By including these safety features, dangerous liquid tanks focus on keeping people safe when dealing with and moving hazardous liquids. They also help protect the environment. These tanks are very important in making sure that harmful substances are kept inside and transported safely, by following strict safety protocols during loading, unloading, and transportation.

The tanks are classified according to the type of hazardous liquid they are designed to carry, including flammable liquids, corrosive liquids, toxic liquids, and explosive liquids. The tanks must be labeled and identified with the appropriate hazard class and UN number, and the driver and transport company must have the necessary certifications and licenses to handle hazardous materials.

Specifications

| Max Gross Weight: | 36.000 kg |

| Tare Weight: | 3.850 kg/8,448 lbs |

| Capacity: | 24.000 L |

T7 Tank Container

The T7 Tank Container is a stainless pressure vessel designed for the transportation of various liquid cargo. Made of 316 stainless steel, it ensures durability and corrosion resistance. Optional features include heating, inert gas protection, and decompressors. It is suitable for oils, alcohol, chemicals, medical drugs, and more. Temperature sensors allow precise control and filling and discharge are convenient through designated openings. With insulation options and customizable designs, the T7 Tank Container offers a reliable solution for liquid cargo transportation.

Tank containers are equipped with several optional features to enhance their functionality during loading and unloading. These include steam or electric heating capabilities, inert gas protection, decompressors, and other necessary equipment for fluid transportation. This ensures the safe and controlled transfer of liquids such as oils (including food oil, cooking oil, and heavy oil), alcohol (including ethyl alcohol), LPG, chemicals (such as hydrochloric acid, nitric acid, caustic soda, hydrogen peroxide, and benzene), medical drugs, fruit juices, honey, hazardous materials, fuels, and toxic substances.

The temperature of the cargo can be precisely regulated through the use of temperature sensors, with the tank container typically made of SUS (stainless steel) materials. Loading and unloading of the cargo can be facilitated by an external pump through the manhole or inlet hole located on the top of the tank, while the self-flow hole at the bottom of the container allows for easy discharge of the contents. To ensure temperature stability, tank containers may be installed with insulation layers made of rock wool or glass wool.

T8 Hydrochloric Acid Chemical Liquid Storage ISO Tank Container

The T8 Hydrochloric Acid Chemical Liquid Storage ISO Tank Container is specifically designed for the safe transportation and storage of hydrochloric acid and other chemical liquids. Its specifications include a dimension of 7100mm in length and 2600mm in diameter. The tank has a capacity of 36000L and is made of carbon steel (Q235) with a 6.2mm thickness for the shell body and an 8mm thickness for the head. The tank container features a round shape and is coated externally with iron red alkyd anti-corrosive primer and alkyd finish paint, while internally it is coated with H52-3 Epoxy Antiseptic Varnish. It undergoes air testing for pressure. The tank fittings include a 500mm diameter manhole, carbon steel ladder, DN80 inlet and outlet ports, and a walkway platform with an anti-skid surface treatment on the barrel top. With its robust construction, corrosion-resistant materials, and precise coatings, the T8 Tank Container provides a secure and reliable solution for the storage and transportation of hydrochloric acid and other chemical liquids.

T10 Tank Container Titanium Tetrachloride Chemical Liquid Storage ISO Tank Container

The T10 Tank Container for titanium tetrachloride chemical liquid storage is a specialized ISO tank container designed for the safe transportation and storage of this specific chemical substance. With an outer dimension of 7100mm in length and 2600mm in diameter, the tank container has a capacity of 36000L and a tare weight of 6.0 tons. It is constructed using carbon steel (Q235), with a 6.2mm thickness for the shell body and an 8mm thickness for the head.

The tank container features a round shape and is coated externally with iron red alkyd anti-corrosive primer and alkyd finish paint, while internally it is coated with H52-3 Epoxy Antiseptic Varnish. It undergoes air testing to ensure its integrity and safety. The tank fittings include a 500mm diameter manhole, carbon steel ladder, DN80 inlet and outlet ports, and a walkway platform on the barrel top with an anti-skid surface treatment. The tank container allows for loading and unloading from both the top and bottom, with valves and connections provided for easy and efficient transfer of the chemical liquid. With its robust construction, precise coatings, and comprehensive features, the T10 Tank Container offers a reliable solution for the storage and transportation of titanium tetrachloride and other chemical liquids.

T11 Tank Container

This ISO liquid tank (T11) is a reliable solution for transporting non-hazardous liquid chemicals, such as food-grade products, water, and certain types of fuels. They are also used in the pharmaceutical industry for the transport of certain types of drugs and other medical products.

Made from corrosion-resistant steel, our tank containers can withstand tough conditions and last for many years. They are built in compliance with ISO standards and are equipped with several features such as relief valves, emergency venting systems, and spill containment systems to ensure the safe transport of liquid chemicals. They also have specialized linings and coatings to prevent contamination and protect the tank from corrosion and erosion over time.

This tank can be reused with the same kind of cargo with proper cleaning and inspection before loading new cargo. With proper maintenance, they can last for many years to come, making them a wise investment. This unit is ready for sale and rent.

Specifications

| Max. gross | 79,366 lbs |

| Tare weight | 8,068 lbs |

| Net Weight: | 71,297 lbs |

T12 - T14 Tank Containers

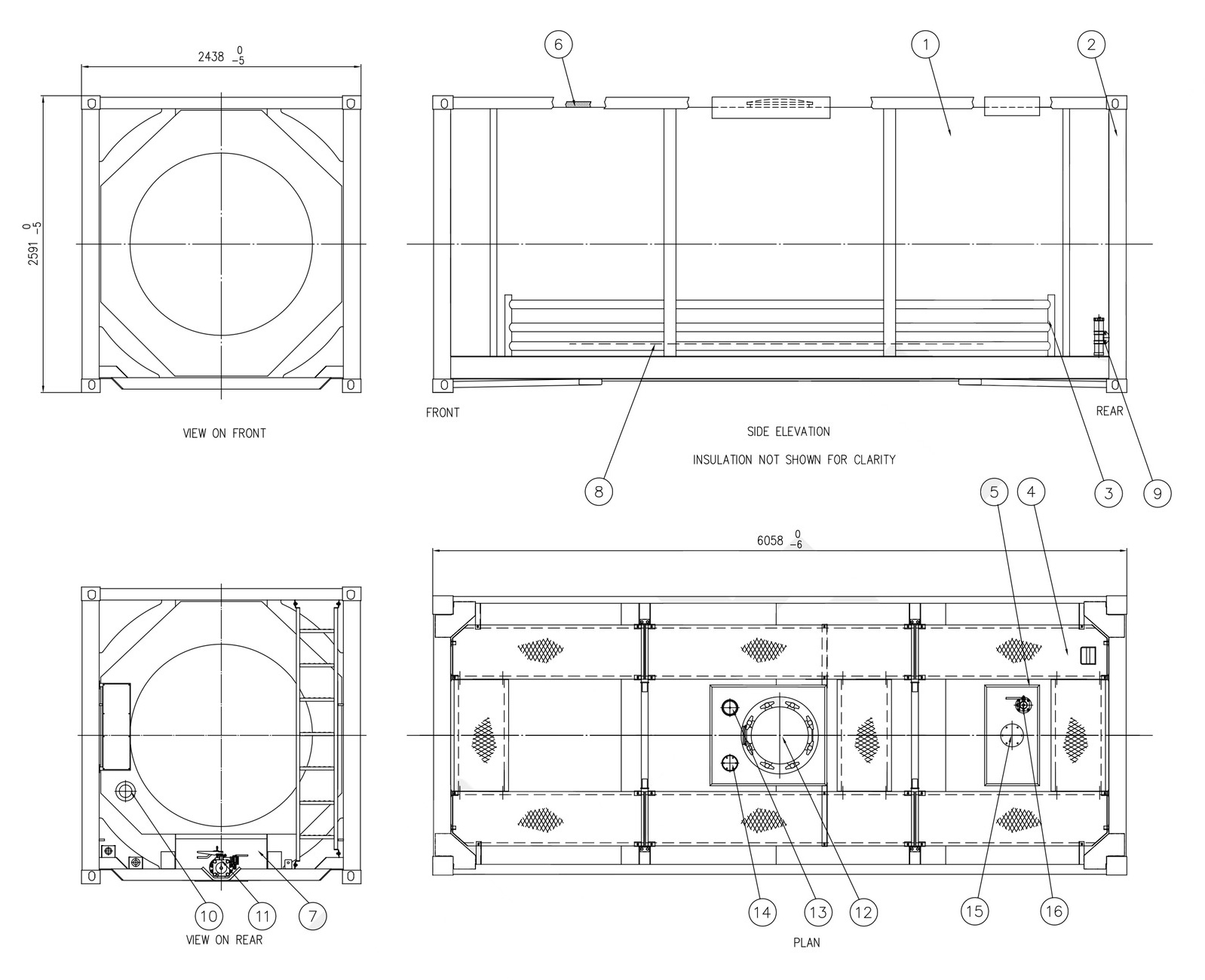

The T12-T14 Insulated & Uninsulated ISO Tank containers are specially designed for the safe and efficient transportation of various types of cargo, including food-grade, hazardous, and non-hazardous materials. These tanks offer a versatile solution with a wide range of capacities to suit different cargo requirements.

The tank containers are equipped with several features to ensure optimal functionality and safety. They include a top discharge flange with adaptable design and optional fill/discharge combinations, a PRV (Pressure Relief Valve) with a vacuum relief valve, and 8 steam heating runs for temperature regulation. The tanks are also fitted with a 45° univalve bottom outlet valve, a “B” type walkway with the option to add handrails, and the availability of baffles for enhanced cargo stability. A non-slip stainless steel ladder is included for easy access to the tank.

The shell and head material of the tank containers is constructed using SANS 50028-7 (2005):1.4402 standards, ensuring durability and resistance to corrosion. These tank containers are available for sale or hire, allowing flexibility to meet specific demands and time requirements. Whether for long-term use or to accommodate peak or seasonal demands, Tradecorp offers reliable equipment solutions for your cargo transportation needs.

T20 Tank Container

The T20 Tank Container is specifically designed to ensure the safe transportation and temporary storage of various liquid cargoes with hazard classes 3, 5.1, 6.1, 8, and 9. It is approved for use in transportable containers that comply with UN instructions, including UN T1-UN T5 and UN T7-UN T20. The tank container offers the added benefit of being able to heat the cargo before unloading, providing flexibility and convenience.

Equipped with thermal insulation, the tank container helps maintain the desired temperature of the cargo during transportation and storage, ensuring its integrity and quality. The inclusion of a Fort Vale stop valve further enhances the safety and efficiency of the container, allowing for easy control and regulation of the flow of the liquid cargo.

For convenient access and maintenance, the tank container features a service platform with folding handrails. This platform provides a stable and secure space for operators to carry out necessary tasks. Additionally, the model T20-220 variant of the tank container is equipped with baffles, which help prevent the cargo from sloshing and ensure stability during transportation, especially in challenging conditions.

With its reliable construction and practical features, the T20 Tank Container offers a trusted solution for the transportation and temporary storage of liquid cargo. It meets the necessary standards and requirements to ensure the safety, efficiency, and integrity of the contained substances, making it an ideal choice for a range of industries and applications.

T21 Tank Container

The T21 Tank Container is specifically designed for the transportation of triethyl aluminum (TEAL) Alky, an organometallic substance with water-reactive properties. This portable tank container is suitable for the safe storage and transportation of liquid cargo such as C6H15Al.

The tank has a water capacity of 1750 liters (1.75m3) and complies with UN3394 regulations. It has a maximum gross mass of 2700kg and a maximum tare mass of 950kg, ensuring efficient handling and transportation.

With external dimensions of 2124mm*1124mm*1300mm, the T21 Tank Container provides a compact and secure solution for transporting organometallic substances. The tank is constructed with high-quality 16MnDR material, ensuring durability and resistance to extreme conditions.

Operating at a working pressure of 5bar (0.667Mpa) and designed to withstand temperatures ranging from -40°C to +65°C, the tank container meets the necessary safety standards. The shell thickness of 12mm and compliance with pressure vessel code GB150 further enhance its reliability.

The T21 Tank Container is specifically designed for the transportation of Triethyl aluminum (UN3394) and is ideal for industries requiring the safe handling and storage of this particular cargo.

T22 Tank Container

The T22 Tank Container is a specialized tank designed to safely transport highly hazardous cargo. The T22 Tank Container provides excellent durability and resistance to corrosion. It features 12 steam heating runs, offering efficient heating capabilities with a 4m2 effective heating area. The tank container also has the option for baffles with vertical or horizontal configurations, providing stability and minimizing liquid movement during transportation. Lined tanks and specific value combinations are available to accommodate different cargo types.

For convenient monitoring, the T22 Tank Container can be equipped with a level gauge, allowing users to easily assess the liquid level inside. The tank is equipped with a 500mm bolted manlid and spill box covers, ensuring secure closure and spill prevention. It is fitted with a “B” type walkway for safe access and has the option to fit handrails for enhanced safety during handling operations.

The T22 Tank Container is designed to meet the stringent requirements of transporting highly hazardous cargo. Its specialized features and customizable options make it a reliable choice for industries requiring the safe and efficient transportation of such materials.

A Few Things to Keep in Mind About Intermodal Tank Type

- Do not swap between chemical-grade and food grade service, even after cleaning, unless specifically validated.

- Clean and inspect thoroughly between cargoes; follow depot best practices.

- Fill 80–95% to minimize surge and allow thermal expansion.

- Maintain equipment to ISO standards and CSC requirements; preventative maintenance avoids downtime and protects cargo.

It is essential for keeping the tank in good condition for its efficient operation. Containers used for international shipping must meet safety standards outlined in the Container Safety Convention (CSC). Failing to maintain the equipment properly can lead to inconvenient downtime, expensive repairs, and potential cargo loss. Establishing a preventative maintenance schedule is highly valuable.

Under the CSC, operators of Container Transport Units (CTUs) must create and follow a maintenance system that covers container inspections, examinations, and upkeep. This system should include maintaining the tank’s frame, and its connection to the pressure vessel, and preventing the loss of service items for portable tanks.

The 9 classes of Dangerous Goods

Different Intermodal Tank Types

The International Maritime Dangerous Goods Code (IMDG/IMO) classifies tank containers into IMO Type 1, IMO Type 2, and IMO Type 5.

IMO Type 1

IMO Type 2

IMO Type 5

For non-refrigerated flammable gases (propane, butane). Special mounting to protect the vessel within the frame.

Note: IMO Type 7 addresses cryogenic or refrigerated liquids (oxygen, nitrogen, CO₂), paralleling T75 service.

Our ISO Tank Containers for Sale and Rent

Selecting ISO Tank Container Products to Meet Your Needs

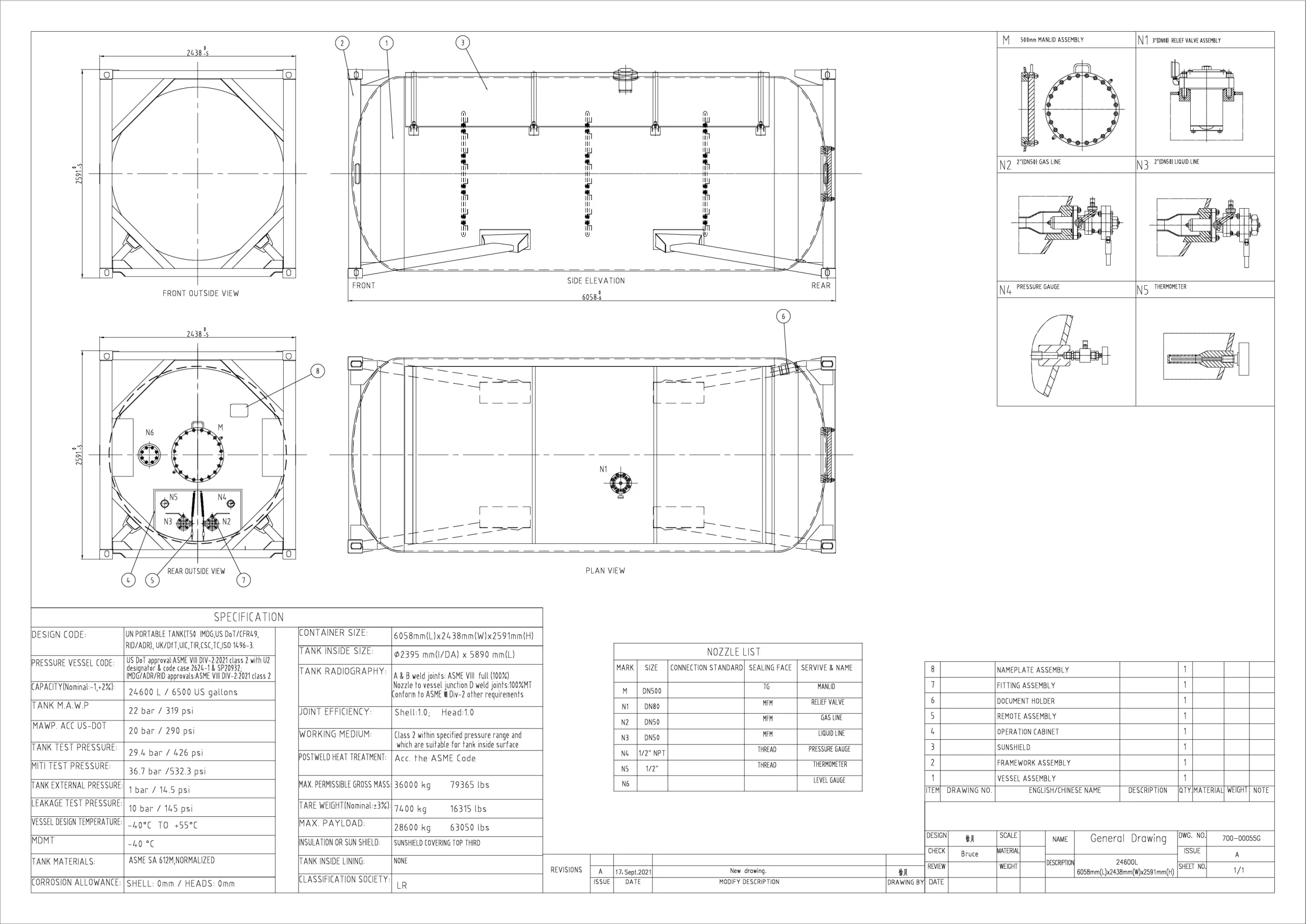

20’ T50 Gas Tank

Specifications

| Max Gross | 79,366 lbs | (36,000 kg) |

| Tare | ~15,983 lbs | (7,250 kg) |

| Max Payload | ~63,382 lbs | (28,750 kg) |

T75 Tank: 20ft & 40ft

Specifications

| Max Gross | 79,366 lbs | (36,000 kg) |

| Water Capacity | ~21,300 L (typical) | |

| Payloads vary by product |

ISO Liquid Tank (T11)

Specifications

| Max Gross | ~79,366 lbs | |

| Tare | ~8,068 lbs | |

| Net | ~71,297 lbs |

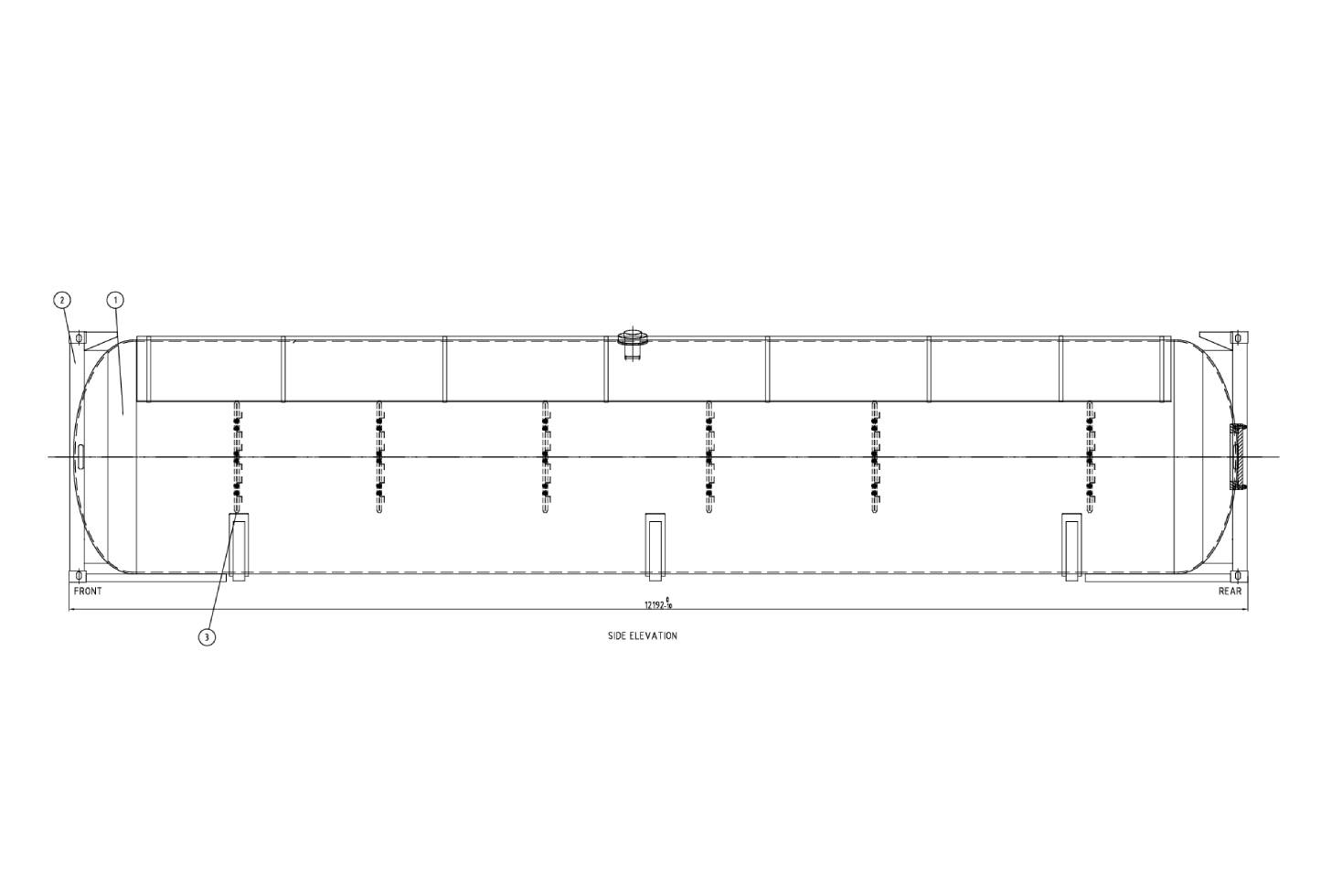

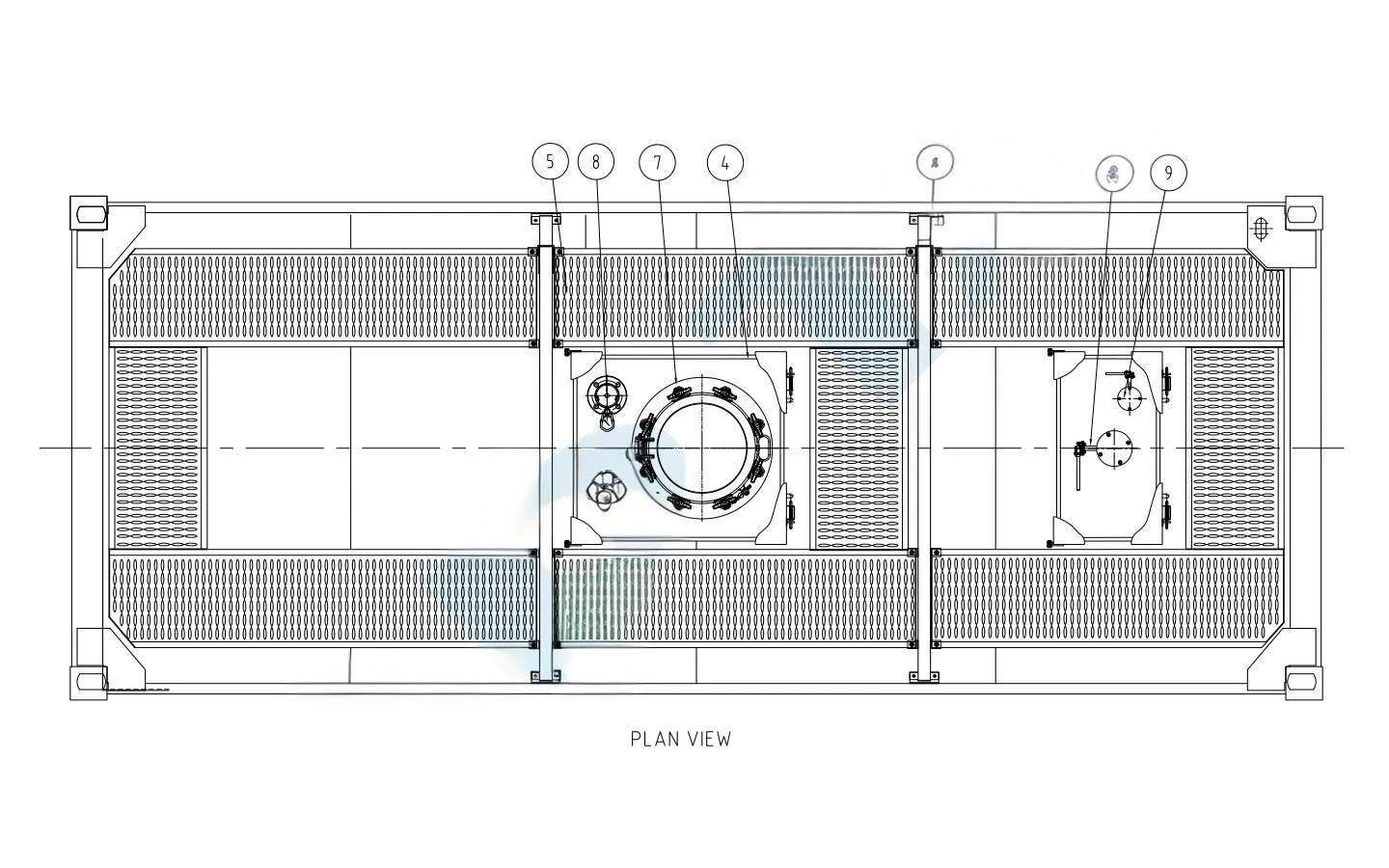

ISO Pneumatic Tank Container

Specifications

| External: | 20’ x 8’ x 8’6” (typical) |

T6 Dangerous Liquid Tank

Specifications

| Max Gross | 36,000 kg | |

| Tare | ~3,850 kg | |

| Capacity | ~24,000 L |

Find the Perfect ISO Tank Container for Sale or Rent at Tradecorp

Tradecorp pairs you with the right iso tank container for sale or rental based on cargo, route, and dwell requirements—then supports you with documentation, depot services, and after-sales care. Whether your priority is transporting liquid safely, meeting ISO certification mandates for hazardous materials, or deploying scalable iso tank storage at destination, our specialists will configure the tank, accessories, and service model that fit.

Ready to move? Inquire Now for pricing, availability, and expert recommendations on iso tanks for sale and rental across your lanes.

Why Choose Us

Tailor-made solutions

Customized ISO tank container solutions to meet your unique requirements.

ISO Standardized

Our containers adhere to international ISO standards, ensuring compatibility and safety.

Sale and Rent

Flexible options to buy or rent ISO tank containers based on your business needs.

Excellent service

Dedicated support throughout the process, ensuring a seamless customer experience.

Extensive expertise

Years of industry knowledge and experience to provide expert guidance and solutions.

Frequently Asked Questions

ISO tank containers comply with ISO standards and can safely transport hazardous and non-hazardous liquids. They are built with stainless steel and have a protective frame that matches the tank’s contents.

The size of ISO tank containers depends on the sizes, types, and conditions. A standard 20ft ISO tank can range from 5,000 to 27,000 liters and can go up to 46,000 liters for 40ft tanks.

ISO tank containers differ from regular containers. ISO tanks are used for transporting bulk liquids and gasses.

The ISO stands for International Organization for Standardization, which regulates the standard for intermodal containers used for storing and carrying heavy loads.

Have Any Questions?

Tradecorp supplies high-quality new and used shipping containers for sale throughout the Americas. Our experienced container consultants can walk you through the purchase process to identify the perfect container that best suits your requirement. Please fill-out the contact form and one of our staff will be in touch.